2026 How to Choose the Best Floor Equipment for Your Business Needs?

Choosing the right floor equipment for your business can be challenging. With so many options available, how do you make the best choice? Quality floor equipment is essential for efficiency and productivity. It impacts daily operations in countless ways.

Consider the specific needs of your business. What type of flooring do you have? Different materials require different machines. Think about the size of the area you need to clean. Larger spaces may require more heavy-duty equipment. A small business may prefer compact and easy-to-store options.

It's easy to overlook important factors. The equipment's maintenance needs and durability are key. A machine that breaks down often can hinder workflow. Investing in the right floor equipment is a commitment. Analyze your choices carefully to ensure a good fit for your needs.

Identifying Your Business-Specific Floor Equipment Requirements

When identifying your business-specific floor equipment needs, consider the environment. Different settings, such as warehouses, retail spaces, or manufacturing plants, require unique equipment. A report from the Facility Industry Journal states that 70% of companies underestimate their equipment needs. This leads to inefficiency and increased operational costs. Evaluate your space in terms of size and layout. Assess traffic patterns to determine which equipment fits best.

Tip: Measure your floor area carefully. Misjudging the dimensions can lead to poor equipment selection.

Think about your workflows. What tasks will the equipment facilitate? For example, if you have heavy-duty lifting required, you might need different tools than if you focus on cleaning or maintenance. According to a National Cleaning Database report, 45% of businesses report operational delays due to inadequate equipment. Make sure you account for future growth and changes in your workflow.

Tip: Consult with employees. They can provide insights that data alone may not reveal. Ensure that your floor equipment meets current and foreseeable needs to avoid costly adjustments later.

Choosing the Best Floor Equipment for Your Business Needs

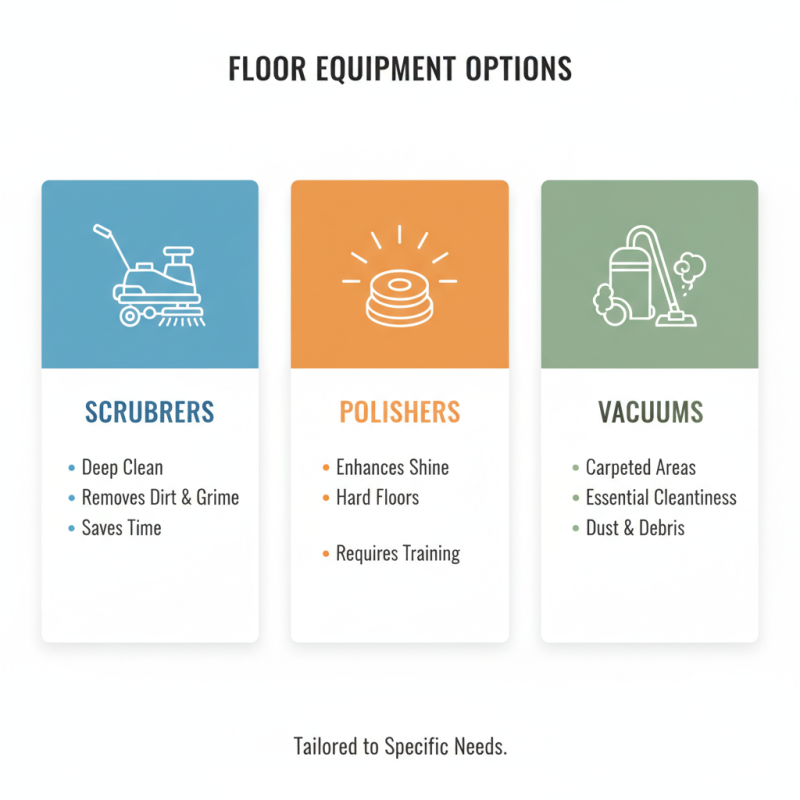

This chart illustrates the importance rating of various types of floor equipment, helping you make informed decisions based on your specific business needs.

Evaluating Different Types of Floor Equipment Available on the Market

When selecting floor equipment, you’ll find various options tailored to specific needs. Common types include scrubbers, polishers, and vacuums. Scrubbers clean dirt and grime effectively. They save time and provide a deep clean. Polishers, on the other hand, enhance the shine of hard floors. They may require special training to operate efficiently. Then, there are vacuums. They are essential for maintaining cleanliness in carpeted areas.

Consider usage frequency when choosing. Some equipment thrives in high-traffic environments, while others suit light usage. Heavy-duty scrubbers may seem ideal but can be bulky. It may be tricky to store them in smaller facilities. On the other hand, compact models are easier to maneuver but may lack power. Think about the size of your space. Access to tight corners is often a challenge. Balancing power with portability is not straightforward.

Another detail to reflect on is maintenance. Some machines need regular upkeep, which can add costs. Evaluating your staff's skill level is crucial too. Inexperienced operators may misuse advanced machinery. You might invest in expensive equipment but find it underutilized. Understanding the specific demands of your space can guide your decision-making process. Pay attention to your operational needs closely.

Considering Maintenance and Durability in Your Selection Process

When selecting floor equipment, maintenance and durability are crucial factors. Equipment durability affects long-term costs and efficiency. Choose tools made from high-quality materials. These last longer and require fewer repairs. Regular maintenance can greatly extend their lifespan.

Consider the maintenance requirements of each equipment type. Some may need daily cleaning, while others require simple weekly checks. Understand your team's capacity for upkeep. If maintenance becomes too burdensome, productivity may decline. It’s important to find a balance between quality and practicality.

Reflecting on past experiences can guide your choices. What equipment has caused issues? How often did it break down? These reflections can reveal patterns. Every business has unique needs. Prioritize equipment that aligns with your operational goals while being mindful of maintenance.

Analyzing Budget Constraints and Potential ROI for Floor Equipment

When selecting floor equipment, budget constraints are crucial. Businesses often struggle to balance quality and cost. A report from the The National Association of Wholesaler-Distributors indicates that around 40% of small businesses cite budget as a barrier to upgrading equipment. This highlights the need for careful financial planning.

Understanding potential ROI is essential. According to a study by the Equipment Leasing and Finance Foundation, companies that invest in efficient floor equipment see an average return of 15-20% over five years. This return can significantly offset initial costs. Evaluating projected savings in labor and maintenance also plays a role in decision-making.

Choosing the right tools is not just about upfront costs. Long-term savings are often overlooked. Businesses should analyze every angle, including downtime caused by outdated equipment. Remember, sometimes, the cheapest option may lead to higher costs down the road. It's essential to reflect on the true value of an investment in floor equipment for sustained growth and efficiency.

Consulting Industry Experts and User Reviews for Informed Decisions

Choosing the right floor equipment can be daunting. Consulting industry experts is crucial. They provide insights based on experience. User reviews also play a significant role. Real feedback helps in understanding performance. Look for trends in positive and negative reviews.

Tip: Focus on your specific needs. What type of environment will you use the equipment in? Consider the size of your space. Do you have heavy foot traffic? This will impact your decision.

While it’s tempting to go for the latest model, don’t overlook older options. Sometimes, well-reviewed older models outperform new releases. It’s wise to read user testimonials, especially about longevity and ease of use.

Tip: Take your time. Gather information before deciding. Rushed choices often lead to regrets. After all, the right equipment should enhance your operations, not complicate them.

Related Posts

-

Unlocking Growth in Floor Equipment Sector at 2025 China Import and Export Fair with Market Insights

-

Top Floor Equipment for Effective Cleaning and Maintenance Solutions

-

Top 10 Effective Floor Cleaning Tips for a Spotless Home

-

Exploring Trends in Pressure Cleaning Equipment at the 138th Canton Fair China 2025

-

Unlocking Market Potential: Soft Wash Pressure Washer Innovations at the 138th Canton Fair 2025

-

Top Floor Cleaning Equipment Trends for 2025 You Need to Know